-

Sand Making Crusher

- PCL-Vertical Shaft Impact Crusher

- SBM Hydraulic VSI Crusher

- VSI5X Series Impact Crusher

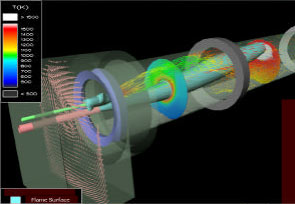

Lime kiln

SBM offers a comprehensive combustion audit, analysis, optimization, and problem resolution for your kiln. Using advanced numerical tools, we diligently obtain comprehensive details of your process in a cost effective manner to:

· Reduce fuel costs

· Solve operational problems

· Increase production

· Reduce emissions

· Increase refractory life

· Optimize kiln operations

· Reduce residual carbonate

· Produce a controlled flame shape

· Significantly reduce decision making risks for retrofits

Kiln issues

Kilns are key equipment in the cement, mining, and pulp and paper industries. They consume a significant amount of fuel and have common operational problems including improper flame shape, flame impingement, premature brick failure, excessive emissions, low product output, poor hood aerodynamics, poor air/fuel mixing for combustion, and low fuel efficiency. These problems are closely related to the flow and heat transfer to the mud and to the combustion processes in the kiln. SBM works closely with clients to determine the root cause of problems by performing comprehensive analysis to determine the most cost-effective solution. Clients are assured of an unbiased and independent source of information for decision making.

The SBM advantage

Detailed information from the analysis is used by process engineers to evaluate “what if” scenarios, by operators to avoid improper operational settings, by mill managers to make informed decisions regarding kiln retrofits, and by the mill to address environmental issues. SBM provides comprehensive information throughout your kiln at relatively low cost.

SBM uses a validated and coupled combustion, convection, diffusion, and radiation models that provide significantly more realistic solutions than non-thermal physical or simplified mathematical models. Results can be applied with confidence to:

· Reduce fuel consumption

· Adjust primary/secondary air and fuel ratios and burner settings to maximize kiln efficiency

· Identify and eliminate thermal hot spots that lead to reduced brick liner lifetime

· Develop strategies for reducing ring formation

· Identify and fix problems with kiln performance due to hood shape and secondary air ports location and size

· Evaluate NCG injection alternatives - optimize injection

· Evaluate alternative fuels

· Minimize emissions

· Optimize heat transfer to mud

· Improve combustion stability through retrofit and adjustment of the burner and burner structure

- About Us

- |

- Service

- |

- News & Events

- |

- Contact Us

- |

- Resources

Aggregate Crusher

Artificial Sand Making

Ballast Crushing Machine

Basalt Stone Crusher

Barite Mine Process

Beneficiation Plant

Bentonite Crusher

Bentonite Milling

Calcium Carbonate Crusher

Calcium Carbonate Grinding

Cement Grinding

Concrete Crusher

Coal Crusher

Copper Crusher

Cement Mill

Chrome Mining Process

Copper ore Beneficiation

Coal Processing

Coal Pulvarizer

Feldspar Crushing

Feldspar Grinding

Flotation Machine

Gold Crusher

Gold Mine Equipment

Gold Processing Machinery

Granite Crusher

Granite Crushing Machine

Granite Quarry Equipment

Gypsum Crusher

Gypsum Mining

Gypsum Powder Production

Iron Ore Beneficiation

Iron Ore Crusher

Kaolin Processing Plant

Limestone Crusher

Silica Sand Crusher

Iron Ore Mining Equipment

Cement Production Line

Talc Production Line

Quartz Crushing Machine

Limestone Mining Process

Manganese Benificietion